As a Lean Six Sigma Black belt and technology professional, I have always had a passion for data. Data tells a story and helps you make tactical and strategic decisions that optimize your business. I like to say it’s ‘evidence-based decision making’.

I’ve been a Lean Six Sigma Blackbelt since 2009. I earned this by improving a global initiative for ‘on and offboarding’ as a service for an internal consulting group in the Pharmaceutical area. This was a clear pain point in our shared services division, so I wanted to solve it. I then went on to manage portfolios of Lean and Six Sigma projects at that organization and later on in the Big 4 consulting environment. As an entrepreneur, I also built a framework to deliver client engagements at 5P with simple takeaways from the framework. Data is the foundation of all good decision-making.

Over the years I’ve been asked a lot of questions about the process. I’ve also heard a lot of feedback that the process is too cumbersome for ‘my organization’. Lean Six Sigma is a toolbox, not a checklist. It’s a framework that you can take pieces out to help you in operational change management and project delivery. It’s scalable based on your need.

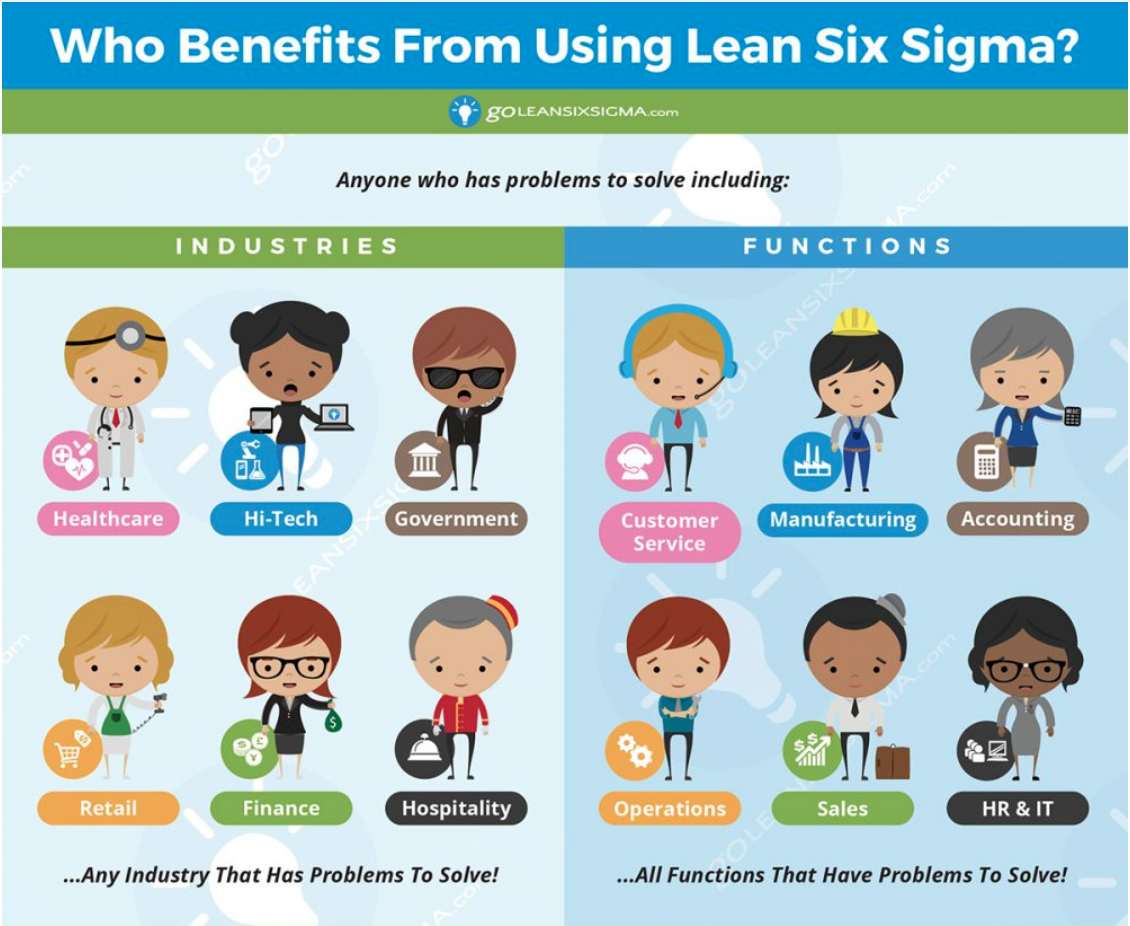

Simply put, Lean Six Sigma is a framework that provides efficiency and elimination of defects in your business environment. It was founded out of the manufacturing domain, but all vertices and functions can benefit from it.

Let me break this down further………

What is Lean and Six Sigma?

Lean improves bottom-line profits and helps meet business goals.

- It eliminates waste while providing maximum value to customers with the lowest possible amount of investment.

- It reduces non-value added (i.e. extra) steps in the process to aid in getting your product or services out quicker in the market.

- It saves you money through efficiency measures by the reduction of waste in your business process.

Six Sigma eliminates waste by reducing defects in your product or service. There are 8 kinds of commonly seen waste.

- Defects – Products or services that are out of specification that require resources to correct.

- Overproduction – Producing too much of a product before it is ready to be sold.

- Waiting – Waiting for the previous step in the process to complete.

- Non-Utilized Talent – Employees who are not effectively engaged in the process.

- Transportation – Transporting items or information that is not required to perform the process from one location to another.

- Inventory – Inventory or information that is sitting idle (not being processed).

- Motion – People, information, or equipment making unnecessary motion due to workspace layout, ergonomic issues, or searching for misplaced items.

- Extra Processing – Performing any activity not necessary to produce a functioning product or service.

*Reference https://goleansixsigma.com/8-wastes/

What is the difference between Lean and Six Sigma?

Essentially both have the same goals of eliminating waste and creating efficiency. However, the main difference between the two is the execution frameworks.

The principles behind the Lean Six Sigma framework are…

- Always focus on the customer

- Understand how work really happens

- Make your processes flow smoothly

- Reduce waste and concentrate on value

- Stop defects by removing variation

- Get buy-ins from the team through collaboration

- Make your efforts systematic and scientific

Lean execution method follows the PDCA framework: Plan, Do, Check, & Adjust.

Six Sigma execution method follows the DMAIC framework: Define, Measure, Analyze, Improve, & Control – All data-driven.

How can I easily implement the Framework in our organization without being a Lean Six Sigma expert?

- First and foremost your team must align on a ‘business problem’ you specifically want to tackle for improvement. Everyone needs to be on the same page and determine the exact initiative you want to improve and turn that into a project.

- Determine who on your team is a subject matter expert for the process. Put them on the project team with the goal of being a change agent for improvement efforts. They know better than anyone else what works, what is broken, and what the future process should look like to make their jobs easier.

- Identify a project manager to lead the effort. The PM should define the actual tools taken from the framework that makes sense for your organization. They can then develop the plan and manage the project. This should include, activities, timelines, people, and dates for a successful delivery.

- Select or create data to measure the before process you’d like to improve and do a Value Stream Mapping exercise.

- Determine your future state utopia and identify gaps from the current state to the future state. This will help you action on what the team needs to do to get to the future state with quick wins and longer-term strategic activities.

- Map opportunities for improvement to organizational goals. Prioritize these based on 6 key areas and then determine, based on these areas, what is the biggest impact on your organization:

- Revenue Opportunities

- Efficiency/Automation

- Customer Self-Service

- Data Accuracy

- Compliance

- Reduction of Defects

- Set up your project plan. Identify the activities, resources, dates, stakeholders, and critical success factors. Identify bottlenecks to achieving success and manage this closely with your delivery team and process champion on a weekly basis. This will ensure delivery success.

- Have your process champion, who is the stakeholder of the project, communicate the importance of the initiative. Have them share scope, set expectations, and rally the team around why this is important for the organization including benefits and outcomes.

- Deliver!! Ensure you are measuring the success of the project’s progress along with communicating any roadblocks on a weekly basis.

- Measure your before and after processes to ensure a return on investment. Include things like lead time, processing time, delay time, handoff time, and wait time. Determine hard (direct impact to P&L) and soft (training, attrition, maintenance, etc.) costs for all the steps in the process.

Use this list to start making changes and start by gathering feedback from your team and putting a list together of the areas of your business that aren’t working well.

Though these steps are a good starting point to implement the Lean Six Sigma framework, you may feel better served having someone who is an expert leading these changes. 5P Consulting’s Project Management practice uses the Lean Six Sigma framework as the foundation for all our services and helped me build our own 5P Framework designed off my experience and background in business efficiency. If you’d like a Business Value Roadmap template reach out and we’d be happy to provide one that is a best practice I personally built. You can prioritize the value of your IT initiatives that align with the business goals.

Y’vonne Sisco – Ormond

CEO | 5P Consulting

We do business smarter through People, Process, Products, P&L with priorities ®

Originally published June 10, 2020.